Imagine a world where machines can anticipate your needs and respond with precision. Behind this futuristic vision are actuators. From the delicate movements of surgical robots to the powerful strokes of industrial presses, motors are the driving force behind modern technology. Explore the fascinating world of drivers and discover how they shape our routine.

An actuator is a device that converts energy into mechanical motion, serving as the backbone of automation systems. From the intricate movements of robots to the precise control of industrial machinery, actuators are the driving force behind modern technology.

In the modern industrial landscape, it is crucial to integrate advanced actuator solutions to achieve optimal performance and reliability in automation processes.

Importance of Actuators in the World of Modern Automation

Actuators, as the fundamental building blocks of modern automation, offer several key benefits that drive productivity across industries.

Enhancing Efficiency and Productivity

Actuators improve operational efficiency by automating repetitive tasks. Studies show that automation can increase productivity by up to 30%, allowing businesses to allocate resources effectively.

Improving Precision and Control

With drivers, processes can be executed with high precision, reducing errors and enhancing product quality. This level of control is vital in industries such as manufacturing and robotics, requiring accuracy.

Facilitating Remote Monitoring and Operation

Modern motors feature advanced sensors enabling remote monitoring and control. It is beneficial for industries that require real-time data analysis to optimize performance.

Types of Actuators Used in Automation

There are many motor types, each with its unique characteristics and applications:

- Electric actuators. They are used due to their simplicity and efficiency. They convert electrical energy into mechanical motion, making them suitable for various applications.

- Pneumatic motors. Utilizing compressed air, they are ideal for applications requiring rapid movement. They are found in manufacturing environments.

- Hydraulic actuators. They use fluid pressure to create motion, offering high-force output. They often serve in heavy machinery and industrial applications.

- Stepper and servo motors. These motors provide precise control over position and speed, making them essential for high-accuracy applications.

Advanced Actuator Technologies

Beyond traditional motors, advanced technologies offer enhanced capabilities:

Smart Actuators

These drivers incorporate sensors and control systems that enable them to monitor their performance, detect faults, and adjust their operation.

Piezoelectric Actuators

They use piezoelectric materials that expand or contract when a voltage is applied. They are known for their high precision and rapid response times.

Shape Memory Alloy Actuators

These mechanisms use alloys that can change shape in response to temperature changes. They are often used in applications requiring precise positioning and force control.

Magnetostrictive Motors

These motors use magnetostrictive materials that change shape when exposed to a magnetic field. They are known for their high force output and durability.

Actuator Applications in Various Industries

Several industries have benefited from actuator integration into their processes, enhancing efficiency, precision, and automation capabilities:

1. Manufacturing

Actuators are fundamental in manufacturing because they enable precise control over machinery, improving production rates and reducing labor costs. For example, electric linear motors serve for pick-and-place applications, allowing for faster and accurate component handling.

2. Automotive

In the automotive industry, actuators facilitate various functions such as automated windows, door locks, and engine management systems. This integration enhances vehicle functionality and improves safety and user experience. The sector increasingly relies on electric movers for their efficiency and reliability in critical applications.

3. Healthcare

The medical field utilizes motors in devices like adjustable hospital beds and surgical equipment. These applications require high precision and reliability to ensure patient safety and comfort. These mechanisms help automate processes that would otherwise be manual, reducing the physical strain on healthcare workers.

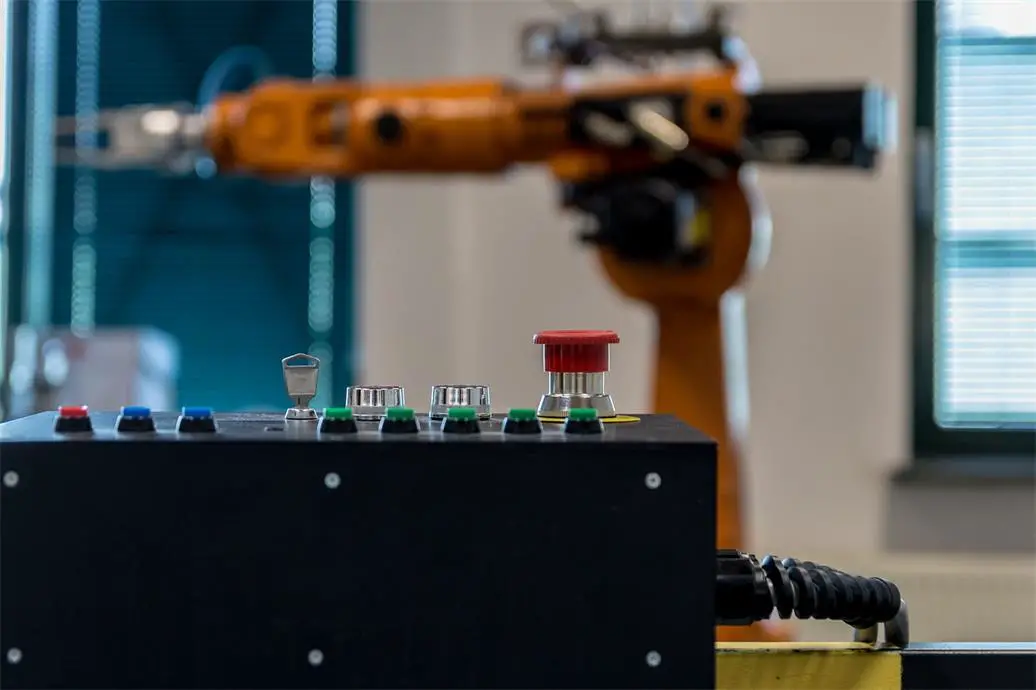

4. Robotics

Actuators are essential in robotics for controlling movement in robotic arms and other mechanisms. They provide the necessary motion to perform tasks such as assembly, welding, and inspection with high precision. The actuator’s versatility allows for their use in many robotic applications across various industries.

5. Food and Beverage

In the food and beverage industry, motors serve to streamline production processes, from packaging to quality control. They help maintain hygiene standards by automating tasks that require frequent cleaning or handling of sensitive materials.

6. Aerospace

The aerospace sector benefits from these mechanisms in systems that require precise control over flight surfaces and landing gear mechanisms. Motors contribute to the reliability and safety of aircraft operations by ensuring accurate movements under demanding conditions.

7. Smart Home Technologies

Actuators are crucial in smart home applications, enabling lighting, heating, and security system automation. This integration enhances user convenience while contributing to energy efficiency through automated controls.

Challenges and Considerations

Despite their benefits, these mechanisms present several challenges you must address for successful implementation:

Selection Criteria for Actuators

Selecting the top actuators for enhancing the functionality of your systems involves considering several factors:

- Cost. Evaluate the initial cost of the motor, as well as ongoing maintenance and energy consumption costs. Consider the total cost of ownership over the actuator’s lifespan.

- Energy efficiency. For applications where energy consumption is a critical factor, compare the energy efficiency of different actuator types. Factors such as efficiency ratings and power consumption can influence overall operating costs.

- Maintenance requirements. Assess the maintenance needs of different motors. Consider factors like lubrication requirements, inspection intervals, and the complexity of maintenance procedures.

- Environmental considerations. If the mechanism will be used in harsh environments, such as extreme temperatures, high humidity, or exposure to corrosive substances, ensure it is suitable for those conditions.

- Safety. Evaluate the motor’s safety features, such as overload protection, emergency stop mechanisms, and compliance with relevant safety standards.

Maintenance and Reliability

Regular maintenance is crucial for ensuring motor’s longevity. Implementing predictive maintenance strategies can reduce downtime.

Integration with Other Automation Components

Successful automation relies on integration between motors and other components like sensors and controllers. Careful planning is essential to avoid compatibility issues.

Understanding the role of actuators in modern automation solutions is a must for anyone looking to enhance functionality within their operations. Select the top drivers suited for specific applications and achieve greater efficiency and reliability in your automated processes.

Leave a Comment